6 Key Ways to Prevent Weld Failures

Use low hydrogen filler metals when possible

Most filler metal manufacturers offer a variety of products, particularly flux-cored wires and stick electrodes that produce low levels of diffusible hydrogen. When welding ferritic (or iron-based) steels, the use of these filler metals can be a particularly good defense against weld failures caused by hydrogen-induced cracking, also referred to as cold cracking. This type of weld failure typically occurs within hours to days after the weld has cooled, and is the result of residual stress from the base material being restrained along the weld, along with the presence of hydrogen in the weld. Thicker materials are more prone to the failure, since they tend to create areas of high restraint and can serve as a heat sink that leads to fast cooling rates — the ideal condition for hydrogen to coalesce and add to the residual stresses in the weld. High-strength steels and applications with constrained joints are also prone to weld failures via cold cracking.

Filler metals with an H4 or H5 designator are a good choice to prevent weld failures associated with cold cracking, as they minimize the amount of hydrogen going into the weld in the first place, and with it, the opportunity to cause cracking upon the weld cooling. These filler metals contain less than 4 or 5 ml of hydrogen per 100 g weld metal, respectively.

In certain cases, using filler metals with a basic slag system can also help reduce the risk of weld failures from cold cracking. These filler metals typically contain high levels of hydrogen scavengers, including fluoride, sodium and calcium that can combine with hydrogen to remove it from a cooling weld.

Take care with fit-up and joint design

Proper part fit-up and good joint design are both key in preventing weld failures, particularly those associated with hot cracking. When presented with either of these conditions, it is not uncommon for a welding operator to try to compensate by creating a wider weld bead to fuse the metal together. The danger in doing so, however, is that the resulting weld may have too thin of a throat, causing it to be weak and create stress on the center of the weld. The result is quite often a condition called bead-shape cracking, which is a specific type of hot cracking, and it appears immediately upon the weld cooling.

A good rule of thumb, when possible, is to design the joint so that the welding operator has easy access the root. Doing so ensures a proper bead depth to width ratio. A good range for that ratio is to make the depth 5:1 to 2:1 the size of the width.

Pre- and post-weld materials correctly

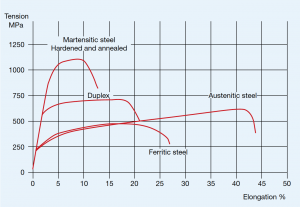

Some materials are particularly susceptible to weld failures due to cracking, including high-strength steels, which have high carbon and/or high alloy levels. Because these materials are less ductile, they tend to generate residual stresses along the base metal and the finished weld during the cooling process.

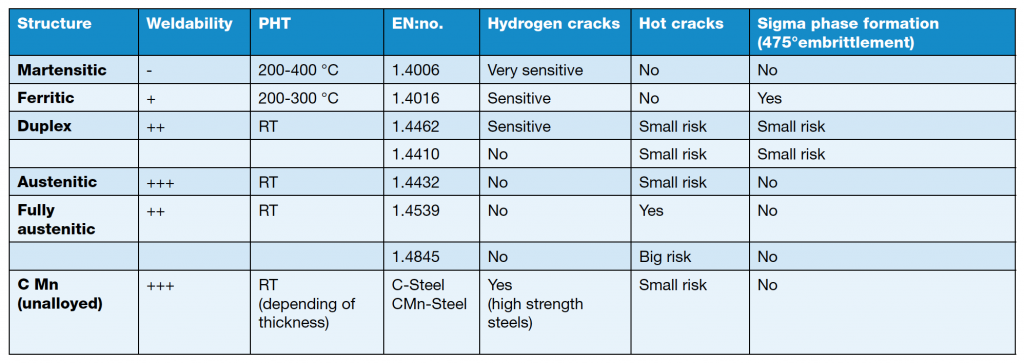

It is important to always preheat such materials for the recommended time and temperature according to the welding procedure, and to ensure that adequate and uniform heat soak has occurred throughout. Preheating prevents rapid cooling and with it helps maintain a more ductile internal grain structure (pearlitic) in the heat-affect zone. It also limits shrinkage stresses in the material and helps reduce instances of martensite formation in the grain structure — areas where hydrogen can dwell and ultimately cause cracking.

Similarly, when called for by a given welding procedure, post-weld heat treatment (PWHT) should be implemented as directed. PWHT relieves residual stresses and drives diffusible hydrogen from the weld to prevent weld failures by way of cold cracking.

Properly match filler metal and base material strengths

Selecting the appropriate filler metal strength can also help minimize the risk of weld failures. Most applications require matching the filler metal tensile or yield strength to that of the base material. The strengths should be as close as possible and selected as applicable to the design requirements of the application. If welding a lower strength material to a higher strength one, always match the filler metal to the lower strength one, as it will allow for greater ductility and help mitigate the risk of cracking. When making certain fillet welds or when welding on an application requiring only partial joint penetration (PJP), it may be desirable to undermatch the strength of the filler metal to the base material. Doing so can sometimes minimize the residual stresses in the finished weld.

Implement proper filler metal storage and handling procedures

To prevent filler metals from picking up moisture, dust, debris or oil that could lead to contamination — and ultimately weld failure — it is critical to follow proper storage procedures. Store filler metals in a dry area in their original packaging until ready for use. Ideally, keep the storage area the same temperature as the welding cell to avoid the condensation that occurs when moving from a cold area to a warm area, which could lead to moisture being absorbed by the filler metal. Allowing the filler metal to acclimate to the temperature of the welding prior to opening the package can also protect against hydrogen pickup that could lead to cracking and weld failure.

Welding operators should always wear gloves when handling filler metals to protect it from moisture from their hands, and they should cover any open spools with a plastic bag when not in use. Doing so protects that filler metal from accumulating contaminants from the air that may lead to poor weld quality and/or failure. Too, companies should never place grinding stations near an area where filler metal spools are present, as particles can settle on the wire, causing potential inclusions in the weld. If using stick electrodes, always follow proper storage and reconditioning procedures prior to welding.

Undergo the appropriate training

The importance of training as a first defense against weld failures cannot be emphasized enough. Proper education helps instill good welding techniques, as well as the ability to make sound decisions that positively affect the welding operation. Welding operators should be trained to always follow the prescribed welding procedure and to troubleshoot the common causes of weld defects, such as undercutting, slag inclusions or porosity that may lead to weld failures. They also need to be trained to attend to the special requirements of the alloys they may encounter. Check with a local welding distributor or welding (or filler metal) manufacturer for training opportunities. They can often assist with initial welding operator training and also assist with their continuing education. If the resources allow, companies may consider implementing their own training programs as well.

In the end, welding operators who know to follow procedure and also adjust properly to the various facets of the welding operation stand a good chance of achieving the desired weld quality and preventing weld failures.

Article based on ITW Welding global experience and knowledge.