What Are Stickout, Electrode Extension and Contact-Tip-To-Work Distance?

Stickout and electrode extension are often used interchangeably. Learn more about the difference and how it impacts weld quality.

Understanding welding terms

Producing quality welds requires attention to detail in setting weld parameters. Even slight changes can lead to significantly different results.

Achieving the right parameters to get the results you want requires understanding and using proper welding terms. Here’s an example I see frequently across the industry: People often use electrode extension, stickout and contact-tip-to-work distance interchangeably.

But these terms measure different things, and using them interchangeably — or not understanding their proper meanings — can cause confusion that alters weld parameters and, ultimately, weld quality.

So, how do electrode extension, stickout and contact-tip-to-work distance differ? Let’s talk about each one and why it’s important to use the proper term.

Understanding the difference

Changing the distance between your welding gun and the workpiece affects the amount of resistance in the welding circuit, and a change to the resistance also alters amperage in a constant voltage process like gas metal arc welding (GMAW). To help ensure and maintain proper amperage in your application, it’s important to know the meaning of these common terms and how they differ:

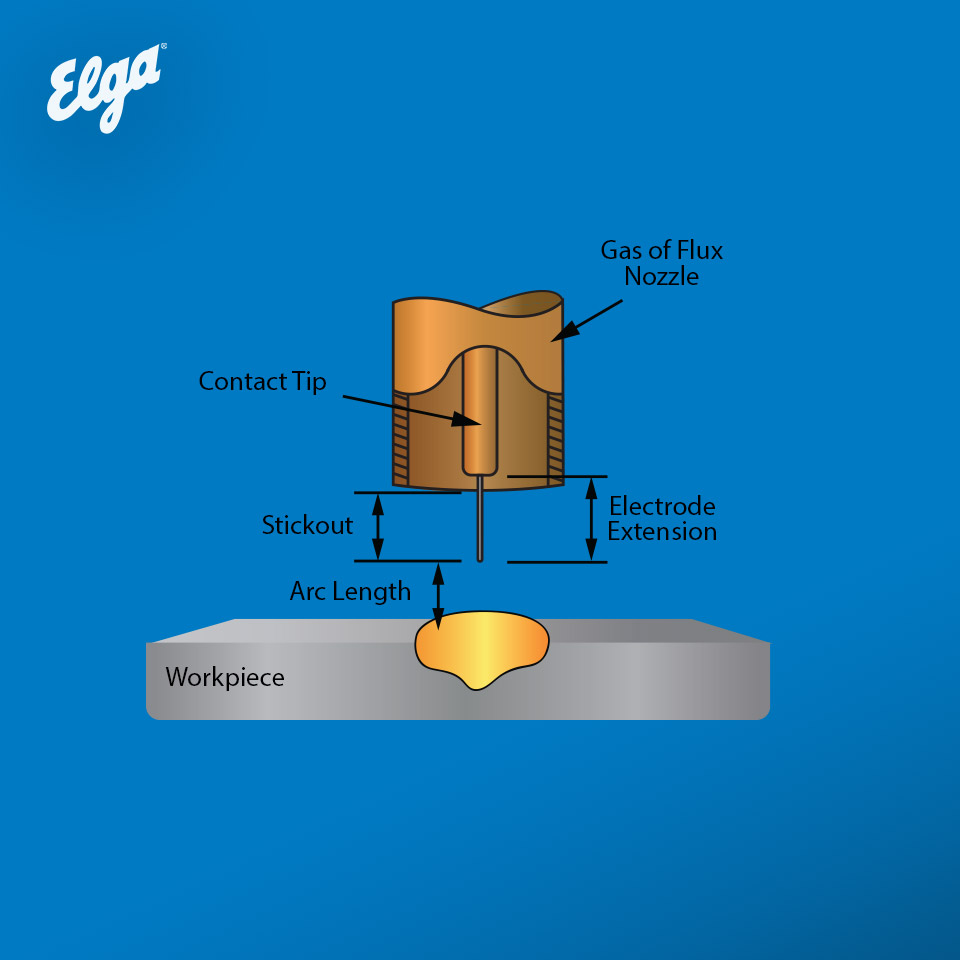

- Electrode extension: As defined by the American Welding Society (AWS), this refers to the length from the end of the contact tip to where the wire melts off.

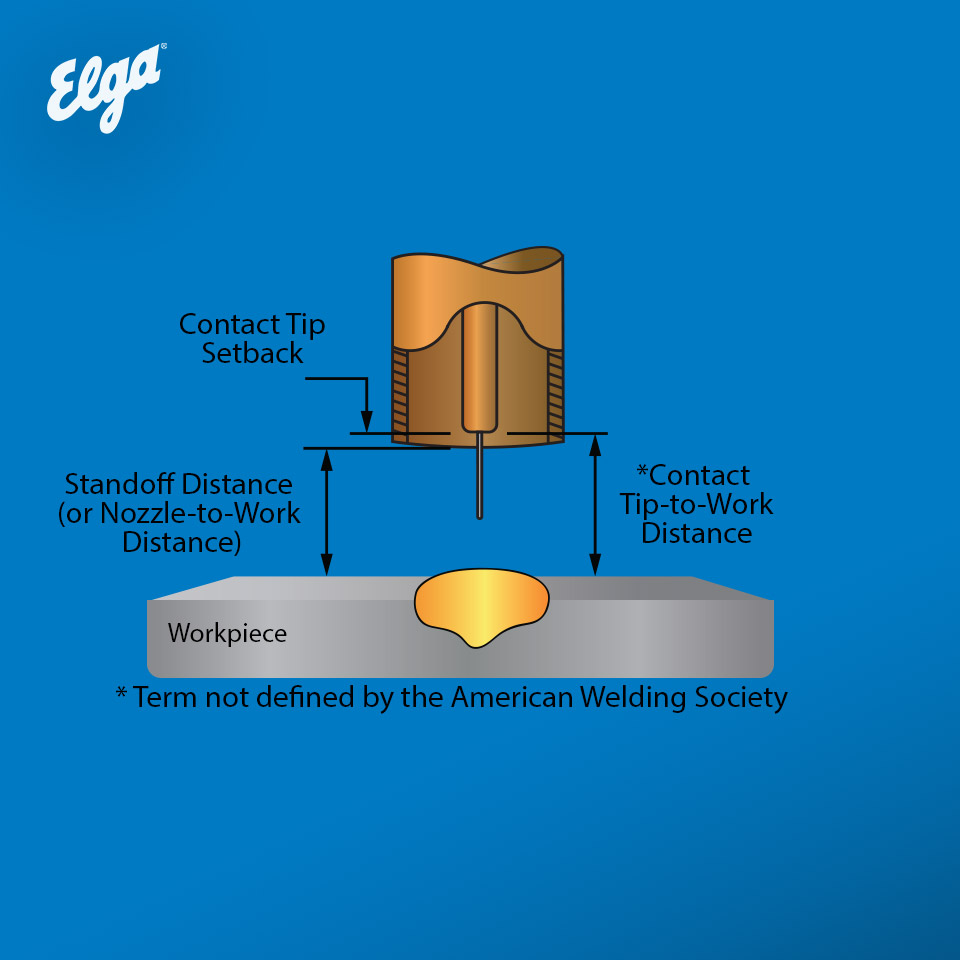

- Stickout: Another common term defined by the AWS, this refers to the end of the nozzle to where the wire melts off. The only time that electrode extension and stickout can be used interchangeably is when the contact tip is flush with the end of the nozzle. In instances where the contact tip is recessed, these two terms refer to different distances.

- Contact-tip-to-work distance: While this is a commonly used industry term — even in many weld procedures — it’s not actually defined by AWS A3.0 Standard terms and definitions. The best time to measure contact-tip-to-work distance is when you’re preparing the weld or programming the robot, and you can take a physical measurement before you strike the arc. Once the arc is struck, arc length is measured by voltage, and electrode extension can be measured by resistance in the circuit or with sight. When people use the term contact-tip-to-work distance, they often mean the sum of arc length and electrode extension.

How it affects amperage

Maintaining consistent electrode extension during welding is critical because varying the extension can change your amperage, which can put you out of range of your welding specifications. When that happens, you may be depositing a weld that’s less than sound.

Too short of an electrode extension increases the amperage and brings you closer to the weld pool, which can cause premature damage to the contact tip and create burn-through from too much heat. Too much extension lowers the amperage and can result in poor penetration that requires rework.

Consider this example of GMAW in spray transfer mode using the same wire type, shielding gas, base metal and nozzle diameter in both instances. The original contact-tip-to-work distance was 19mm, resulting in 235 amperes. With nothing else changing except the contact-tip-to-work distance, simply changing that from 16mm to 25mm causes amperage to operate in a window from 282 to 213 — which could put you out of spec for the application.

This happens because increasing the distance causes an increase in resistance — and the amount of resistance in the welding circuit can make or break your weld quality. To see just how much even small changes to this distance can affect amperage, you can play around with changing the electrode extension in your noncritical welding applications.

Improve weld quality

Contact-tip-to-work distance is often the most logical term to use in welding applications. But it’s important to know that electrode extension, stickout and contact-tip-to-work distance all have specific definitions, and using them interchangeably can cause confusion that puts amperage out of the specified range.

It’s especially important to use the right industry standard terms when communicating globally about welding applications — to help ensure that all parties are on the same page.

The bottom line: Understanding the terms being used provides clarity that can help prevent mistakes and rework.

Tags: FCW, MATRIX, MCW, MEGAFIL, MIG/MAG, Problem Solving, Welding